Where do you store all the Equipment and Supplies?

Equipment, materials and supplies storage are always a workstation design issue. Organizing materials to coincide with the flow of the work creates efficiency.

If there is not enough storage area at the workstation, making the table larger is not necessarily the answer. In fact, the tabletop surface should not be considered storage space. When the work surface is cluttered with supplies, actual working space is reduced.

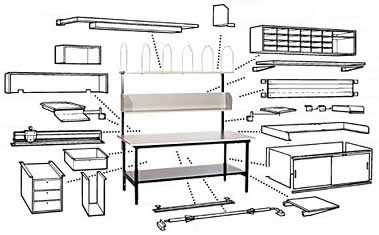

However, every workstation has potential for significant storage. Let’s look at a typical worktable.

There are 4 basic storage areas around a typical table.

- The front of the table

- The left side of the table

- The right side of the table

- The area behind the worker

The four storage areas are typically broken down into eight reach zones.

The four upper reach zones are areas accessible without bending and awkward movements. They are the zones that typically hold the most frequently used or most popular items and equipment.

The four lower reach zones are used more for bulk storage, larger items and slower moving materials. Access typically requires extra steps, bending and sometimes awkward reaches and movements.

The movement required to access a reach zone determines the “zone rating”.

- The front area-upper zone (prime space- little or no movement required from basic work position)

- The left area upper-zone (turn or step- no bending)

- The right area upper-zone (turn or step- no bending)

- The rear area upper-zone (1 or 2 steps-no bending)

Each of the four storage areas also has a lower reach zone. This space is typically not as efficient, since the worker has to step and bend to select material.

When workers move from their neutral position, they have to return to the neutral position. Therefore, the time used for every step is literally doubled. While these time increments seem minor, the accumulation of lost time can add up quickly if operations are inefficient.

How much storage is required?

In order to address the storage issue, it is necessary to compile a detailed list of equipment and supplies used at the workstation. The functional design of the worktable is directly related to the type and volume of supplies and equipment.

Create an equipment and supply bill of materials. Break the list into three parts.

- Machines and Equipment

- Materials and Supplies

- Miscellaneous Items and Personnel Items

Make sure the list is complete and detailed with number of items, flat box sizes, equipment dimensions and a complete list of supplies and related items. It is important to get an exact measurement on the volume of material.

Machine and Equipment Analysis

|

|

|

|

When machines and equipment are a part of the workstation function, they have to be readily accessible when required.

Materials and Supplies Analysis

Workstations typically have a variety of supplies. This part of your planning is one of the most important steps, be thorough and be detailed. Some examples:

- Boxes - (List each size and the flat size)

- Bags and Envelopes - (List each size)

- Void Fill Material- (List each type, roll width and diameter or amount of space required for storage)

- Miscellaneous supplies - (List tapes, labels, envelopes, pens, markers and other small items)

- Small parts, fasteners, inserts Etc. List the details.

Miscellaneous Items and Personnel Effects Analysis

There may be miscellaneous related items that will need to be stored at the workstation. Some examples include:

|

|

|

Often these items may be required to complete the task. Storage space needs to be provided.

Rate the Supplies in ABC Stock Order

Analyze the list of equipment and materials to determine which items are used most frequently.

Typically about 10 – 30% of the material will fulfill at least 40 – 50 % of the tasks. These are the “A” Items.

The next 20 –30% of the material will usually satisfy another 20 –30 % of the tasks. These are the “B” items.

The Balance of the materials which are infrequently used are designated The “C” items.

Next establish a workflow pattern so the “A” materials can be stored in the typical sequence of use. This allows the worker to have the right material at hand as the task progresses.

Choose the correct storage components

Most bench systems have a selection of components consisting of shelves, bins, racks, and other hanging components to make the above the bench and below the bench reach zones efficient and flexible.

Modular bench systems provide numerous alternatives for storing various equipment and materials in the front upper and lower reach zones of the workstation. As applications change, new components can be added to incorporate additional product into the work center.

Storing material on the left, right and rear storage areas.

There are various carts, shelving units, racks, bins, skids, stands, conveyors and other systems readily available in the marketplace to make side and back storage space efficient and well organized.

There are various carts, shelving units, racks, bins, skids, stands, conveyors and other systems readily available in the marketplace to make side and back storage space efficient and well organized.

It is a recommended that whichever system you choose, the area should contain at least two levels of storage. Access to supplies without bending and heavy lifting reduce the chance for injury.

Sharing storage space

When workstations are placed back-to-back, materials stored in the upper front reach zone can be shared.

When workstations are placed back-to-back, materials stored in the upper front reach zone can be shared.

Workstations placed next to a conveyor, directly across from each other, can share common storage space over the conveyor. If worktables are in a row with the workers back-to-back, the storage area behind each worker can be shared.

A few words about restocking supplies

In the process of laying out the equipment and supply storage strategy, think about how supplies will be replaced. If the refreshing process requires the worker to stop, productivity will fall.

When refreshing table materials, it is an advantage to be able to do it from the backside of the table. The left, right and rear storage areas typically use shelves, racks or stands with casters which allow the supplies to be wheeled clear of the workspace for restocking.

Work-in-process and finished goods storage

Finally, there has to be space at the station for incoming work, in process staging and staging for completed tasks. This may often consume a considerable amount of the peripheral area.

Frequently the finished goods are transported away by conveyor. Space over the conveyor can still be valuable storage area.

FREE! Workstation Storage and Design Analysis

Designing the prototype and floor plan for any work area can be very challenging. Every application has its unique issues and limitations. We will be happy to discuss your application and give you our recommendations --- NO COST ---NO OBLIGATION.

Our engineers have over 30 years of experience in analyzing and recommending efficient, ergonomic solutions for all types of Industrial Workstation Applications.

If you would like a free analysis, click here to E-mail your request. Please include your phone number so we may contact you.